Commissioning & Qualification

Commissioning and Qualification

BPS provides expertise in the start-up, commissioning and qualification of biologics production facilities only. Our projects have ranged from single skids to support of major facilities. BPS’s staff has the right mix of process, operations, technology and regulatory experience to identify and implement the best solutions.

Lean GMP

The lean GMP method provides a detailed review and understanding of your quality systems and gives you an opportunity to eliminate procedures that have little or no impact on final facility approval. To achieve this, we look at current and upcoming industry GMP trends to reach a compliant level with a minimum of resources. Where appropriate and where possible we leverage the quality assurance activities of equipment vendors, factory acceptance tests and commissioning activities to minimize the cost and time involved in the final duplicate validation activities. The end result is that facilities are commissioned and qualified quicker and with fewer deviation.

Life Cycle Approach

We employ the “life-cycle” approach to commissioning and qualification. This approach defines the requirements for design, procurement, pre-delivery inspections, factory acceptance testing, installation, commissioning and qualification during the earliest project phases to allow for an integrated approach to qualification. We will work with other design, construction, and commissioning teams to ensure that testing activities, such as pre-delivery inspection, factory acceptance testing, site acceptance testing, commissioning, and qualification are appropriately planned, documented, and completed in sufficient detail and depth to support later life-cycle requirements. The results from each project phase will then support the next phase in the life cycle.

Commissioning

BPS staff has the expertise and the knowledge to ensure your commissioning project starts off and proceeds smoothly to completion using the following basic methods:

* Develop and implement the commissioning plan.

* Plan and coordinate the QA activities of equipment vendors, construction contractors and the client.

* Develop commissioning inspection and test procedures, forms, and protocols per client and project specifications and guidelines.

* Optimally integrate commissioning with the overall project schedule.

* Document the inspections, start-up, and initial testing of equipment to streamline the follow-on qualification activities.

Qualification

We develop qualification master plans, qualification protocols (IQ/OQ/PQ/DQ), perform field inspections, conduct testing, and generate final reports.

Tailor Made Services

We provide the following services tailored to the project needs:

Major Commissioning and Qualification Services

| Commissioning | Qualification |

| * Commissioning/Start-Up Plan | * Validation Master Plan |

| * Commissioning Management | * Quality Assurance Plan |

| * FAT Protocols and Executions and Management | * Protocol and Template Development and Approval |

| * SOPs | * Design Qualification |

| * Parts Washer Cycle | * Protocol Execution and Final Reports |

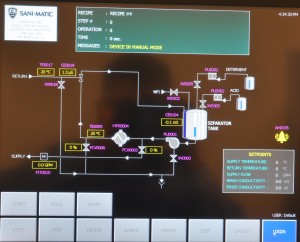

| * CIP Cycle Development | * Computer System Validation |

| * SIP Cycle Development | * Continuing Validation Studies (CIP/SIP) |

| * Punchlist and Maintenance | * Turn Over Packages |