About Us

Overview

Since incorporation in 1997, BPS has been providing the highest level of professional, skilled and customer orientated services to pharmaceutical and biopharmaceutical companies.

BPS has experience in the technologies and processes that are critical to your business. We have direct experience in commercial processes for recombinant proteins, monocloncal antibodies and vaccines expressed in yeast, E. Coli and mammalian cell culture. We will integrate or substitute for the client’s process and technology groups. We will provide you with the expertise and resources for your new project, be it designing a new facility, renovating an existing one or working with a third party contract manufacturer. Over the years we have worked on some of the largest pilot plants and commercial factories making millions of doses annually.

Surj Sengha is BPS’s founder. He has been intimately involved in the Biologics and Biopharm businesses since the biologics and genetic technology revolutions gained traction in the mid 1980s. Our strategy is simple – work hard, pay attention to the details, and control growth based on our ability to make such growth transparent to our customers. We will not sacrifice our service quality for the sake of growth.

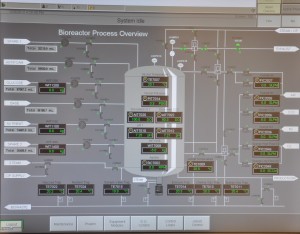

BPS staff is knowledgeable about the design, automation, start-up, commissioning and qualification of typical pharmaceutical and biopharmaceutical equipment and processes. This includes fermentors, bioreactors, downstream equipment, tanks, CIP/SIP systems and purified water systems as well as disposables used in the industry.

BPS has process expertise in all biotech operations such as washers/sterilizers, buffer preparation, fermentation, cell culture, harvest, purification, bulk filling and production of GMP lots.

Our staff is the key. It takes time to find, train and groom the correct people. We don’t take on projects we cannot support.

Process

The biologics process equipment business is composed of many suppliers. Over the years, BPS has built an extensive experience base with numerous suppliers and their different products. This experience base allows us to determine the appropriate suppliers for our client’s applications. The level of detail ranges from individual pieces of equipment down to the component level of laboratory, pilot/development and production scale.

Equipment and Component Preparation

- All brands of autoclaves and parts washers

- Cart customization for autoclave and parts washers

- Sonicator baths

- Preparation and autoclaving of disposable sets

Clean Utilities/CIP/SIP

- Purified Water, Water-For-Injection (WFI) and Clean Steam (CS)

- Clean dry process gases (Air, O2, CO2 and N2)

- Liquid Nitrogen for Cryo-Freezers

- Portable and fixed CIP skids

- Portable and fixed Steam-out-of-place stations

Fermentors/Bioreactors

- Stainless steel systems for E. coli and Yeast

- Stainless steel and single-use systems for CHO and Hybridoma cultures

- Single-use roller bottle, cell factories and cubes for various applications

Media/Buffer Preparation

- Stainless systems for of media/buffer preparation and distribution

- Disposable bag filling

- Media/Buffer filtration

- Sterilization, dispensing and point of use distribution

- Buffer totes for disposable containers and liners.

Product Recovery

- High pressure cell rupture (“homogenization”)

- Continuous (disc-stack and tubular bowl) centrifuges

- Depth filtration

- Micro-filtration and ultrafiltration systems

Purification/Formulation

- Liquid chromatography technologies and applications for vaccines and biologics

- Chromatography columns (stainless steel, acrylic, manual and automated)

- Column packing, storage, cleaning and maintenance

- Virus filtration

- Sterile filtration/bioburden reduction

- Bulk product formulation

Aseptic Filling/Lyophilization

- Pilot and production scale vial filling/stoppering/capping

- Depyrogenation tunnels

- Lyophilizers

Single Use/Disposables

- Tubing set design and selection

- Integration with non-single use process skids

- Roller bottle, flask and Cell Cube technologies

- Wave type bioreactors (up to 200L working volume)

- Skidded bioreactors with liners

- Specialized single use and non-disposable instrumentation

- Liquid filters

Single Use – Cell Therapies Applications

- Disposables sets (culture and perfusion equipment)

- Single use instrumentation and integration with existing DSC/other systems

- Disposable wetted path centrifuges

- Small scale Fill/Finish

- Formulation and mixing

- LN2 cryo-freezing and cycle development

Components and Other Parts

- Individual pump, valves and other wetted components selection

- Seals, gaskets and “O” ring selection for proper use

- Filter membrane and disposable component selection

BPS Inc.

119 Jaffrey Road

Malvern, PA, 19355

| Phone: | 484-614-0869 |

| Fax: | 610-296-1454 |