Consultancy

With an in-depth experience of biologics processes and science, BPS can provide you with the right support in every project phase to help you implement the best solutions. This advise includes estimating manufacturing capacity, evaluation of new technologies and optimization of existing manufacturing processes. It is often possible to save a considerable amount of money and cut the project time by using alternatives to new equipment, smaller equipment, different more efficient use of equipment.

Process Modeling, Simulation and Optimization

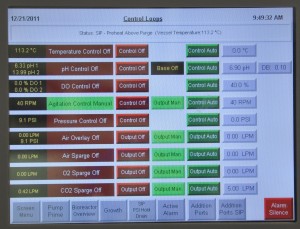

This activity is only really valuable if the model developer truly understands the process and can rely on other in-house expertise and be able to ask the right questions when setting up the model with the client. The model can be as simple as a single spreadsheet for a single CIP skid loading or full train integrating various manufacturing areas (e.g. utilities, media/buffer prep, fermentation and recovery/purification). For the majority of applications we use Designer Pro backed up by EXCEL and Visual Basic as necessary.

The outputs from the models allows us to perform a quick modeling effort based on production capacity parameters to generate timelines (Gantt charts) and resource histograms, identify bottlenecks within process or support systems, and determine the impact of debottlenecking solutions.

We use a desired production capacity to model the process and optimize the usage of equipment and support systems. “What if” scenarios are developed to determine potential bottlenecks (e.g., capacity increase, batch size, multi-product capability, process variations). Proposals of optimized debottlenecking solutions for prioritized future plant requirements can be incorporated into the initial design to achieve process flexibility and minimize overall capital cost.

Single Use Components

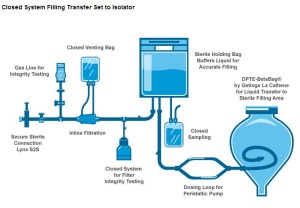

We will help you to develop the optimal strategy for your future production needs in accordance with your business plans. We have direct and extensive hands-on knowledge of the current and emerging disposables market. In fact, BPS staff has been working on these since the only things that were available were disposable silicone tubing, air filters and plasma bags.

- Review current procedures to identify opportunities to decrease costs.

- Improve process sterility/sanitary methods and speed up operations with less in-house preparation.

- Cleaning and sterilization requirements.

- Develop and model process using a substantially or completely single-use component.

- Identify the correct Tubing, bags, filters, disposable purification media and other sterile connectors/components.

- Identify and qualify the 3rd and 4th parties often involved in the procurement, packaging and sterilization of assemblies, sets and sub-sets.

Technology Platform Conversions

BPS can help you with the engineering and scientific intricacies of converting existing equipment (cell culture to fermentation or fermentation to cell culture). The conversion extends to identification of any technologies not normally used in the current platform. For example, a virus removal step is normally a component of a cell culture platform.

Materials Re-use

We can help you develop and validate robust methods for multiple re-use of chromatography resins, micro-filters and ultra-filters. Multiple re-use can save you a considerable amount of money if done right, done at the right time and executed expediently.

Buffer Dilution Systems

We can help you review the pros and cons of off-the-shelf or custom systems for preparation and use of buffer concentrates and in-line/point-of-use buffer dilution delivery systems

Biogenerics

Let us help get a lead in the Biogenerics/Biosimilars/Follow-on Biologics business. We can get you started in conversion to the biogenerics business wether you are a biologics company, equipment maker, disposables products maker or a contract manufacturer.

GMP Audit and Consulting

BPS can provide you with auditors experienced in FDA and EMEA methods to get you ready for GMP inspections. Following the audit you will know what to expect from these agencies when they do really inspect your facility. The auditors will potential problem areas and suggest effective remedies. The audit can be for the following stages of a product or facility life cycle:

- FDA/EMEA pre-approval inspections.

- Modifications to an existing facility.

- Review of employees understanding of cGMPs.

- Supplier audits.

BPS Inc.

119 Jaffrey Road

Malvern, PA, 19355

| Phone: | 484-614-0869 |

| Fax: | 610-296-1454 |