Service Examples

Biologics and Vaccine Facilities

Equipment/Project

- Conceptual design through C & Q support (PFDs, Data Sheets, Design Summary and IOQ) for a large-scale yeast fermentation and purification process.

- Detailed design reviews (Datasheets, Specifications, FAT, SAT, review and approval of 3D Models) for a yeast based vaccine facility.

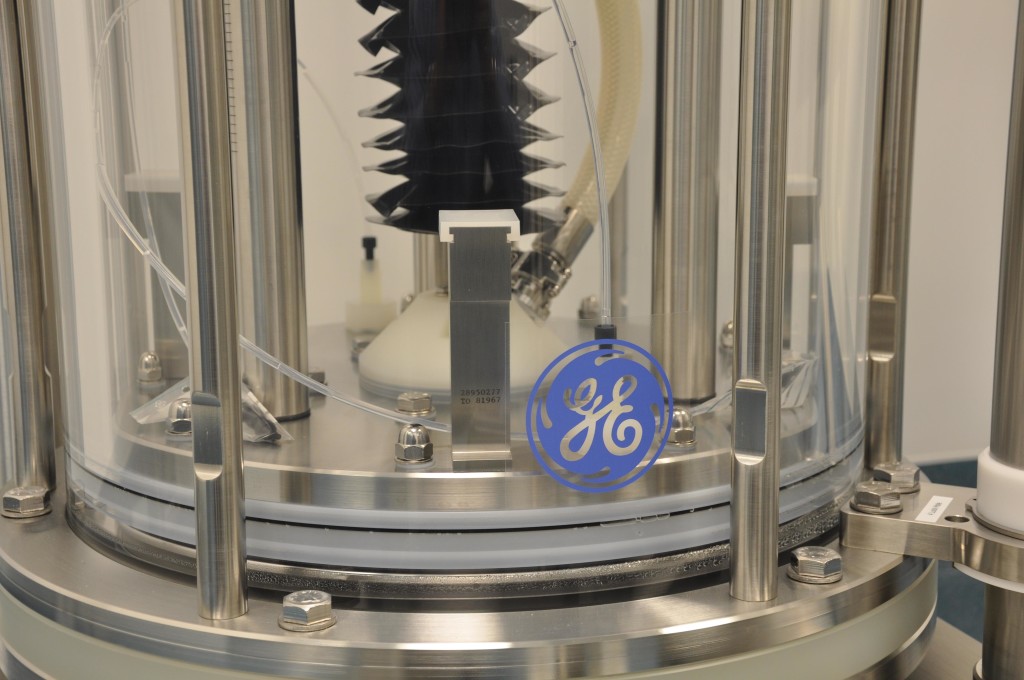

- Design review and design development (PFDs and URSes) for all new process equipment skids (e.g. bioreactors, chromatography systems, UF/DF system and CIP skid) for a Mab facilty.

- Design reviews (BOD, equipment list, layouts, PFDs and GAs) for chromatography systems, MF/UF systems and portable vessels, prototype bioreactor, product hold vessels, depth filtration skid, support utilities and facility layout for a cell culture facility.

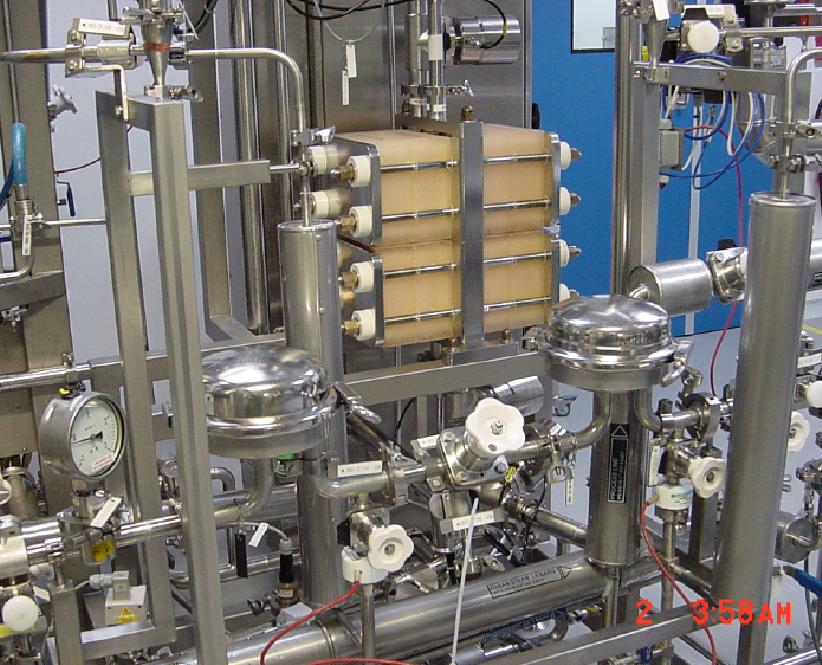

- Design documentation, model development, management of vendor install of equipment, FAT and SAT for Buffer Prep/Hold Skids, Micro/Ultra-filtration and Chromatography for cell culture

- Design review, FAT, commissioning and start-up support for upstream purification equipment (product hold vessels, CIP skid, HWFI skid, temperature control modules and utility expansion of clean steam, clean air, plant steam and chilled water).

- Design support for all process equipment and process utilities including multiple 12,500L bioreactors and bulk shipping containers for biologics facility.

- Conceptual design through SAT for Buffer Tank Preparation and Hold suites for a Mab facility.

- Detailed design through SAT for custom Process/Sonication/Filtration skid and bulk Sterile-Filling Skid.

- Reviews for both upstream and downstream equipment for Mab facility.

- Project Management function from the conceptual design phase through detailed design of a 100MM cell culture manufacturing facility expansion and utilities upgrade.

- Management of vendors (off site construction and on-site install) and management and execution FAT and SAT of process skids for cell culture facility.

- Specification and procurement support of fermentor and cell culture equipment including re-folding tank and large-scale disc-stack centrifuge for bacterial process facility.

- Submittals review and approval (P&IDs, General Arrangements, Datasheets, and Specifications) for a Sterile Adjuvant System.

- Process consulting services for Cell Culture Media process and WFI System project.

Automation/Controls

- Automation support for a 51,000 square-foot GMP mammalian cell facility (DeltaV®, 10 equipment skids, and Vial Fill Line).

- Operating and troubleshooting software, hardware and integration issues between DeltaV, Unicorn, and AB-PLC systems.

- Development of URS/FRS/DDS for automated process chromatography skids, packing skid and MF/UF skids.

- Conversion from legacy Provox® platform to DeltaV® platform (control loops, recipes, phases, equivalencies, data archiving and process quality).

- Design and implementation of fermentation feed and control strategy at large-scale including characterization of kLa, tip speeds, mixing times and response times.

C & Q

- Commissioning Master Plan, Test Plans, execution and validation support for many vaccine facilities.

- Commissioning and validation support for WFI, RO/DI, glycol, biowaste, waste neutralization, CIP systems, chillers, re-heat coils, boilers, plant steam, clean steam systems and Siemens BMS for a complete facility.

- Start-up, troubleshooting and commissioning of production scale bioreactors, CIP, and MF/UF systems and LC systems for Mab facility.

- FAT, start-up, commissioning, troubleshooting and validation support for GMP autoclave for biologics facility.

- Start-up, commissioning and troubleshooting of Buffer prep/hold, Microfiltration, Chromatography and Ultrafiltration skids for vaccine facility.

- Vaccine manufacturing facility start-up, CIP/SIP cycle development and validation (IOPQ).

- Preparation and execution of FATs, SATs and IOPQ for improved manufacturing processes for vaccine processes.

- Development of Sterility Assurance Validation Master Plan. and authoring of summary reports.

Process/CIP/SIP

- Performance of lab scale studies (raw materials approvals from new vendor, piping materials compatibility study and valve leak tests).

- Building-wide diaphragm valve replacement project.

- Laboratory autoclave study (suitability for validation) and valve and filter housing SIP studies.

- Development of through-put data and cost estimates for Sterile Supplies equipment (washers, autoclaves and dry heat ovens).

- Development of Steam-out-of place cycle for alternating Tangential Flow Filters and depth filter housings.

- Process model reviews.

- Design and shakedown of CIP and SIP routes for process skids.

- Remediation of a buffer prep and buffer hold equipment (P&ID’s and recommendation of modified CIP/SIP flowpaths).

- Equipment/facility solutions for process equipment Change Control, equipment electrical modifications, PM scheduling, utility modifications, facility shutdowns, and other associated tasks.

- Process development for new Sterile Blow Fill Seal products.

- Manufacturing process transfer for commercial production of bulk drug product.

- Development of process parameters for recovery steps (liquid-liquid extraction, refolding, liquid – liquid separation, filtration and clarification via TFF/centrifugation).

- Troubleshooting and commissioning for production scale fermentor and associated process equipment.

Quality/Quality Systems

- PLA preparation, operator training, SOP development and change controls.

- Deviation Management/investigation of Atypical Process Events.Troubleshooting. of deviations and resolution of manufacturing problems.

- Design and execution of feasibility studies and development of Batch Records for new manufacturing processes.

- Process Validation, Stability Protocols and Batch Record re-design for recovery, purification and media/buffer steps.

- Product Impact Assessments for sterile vaccine products.

- Continuous Process Improvement & Development of CAPA

- Design and modification of process skids to comply with sterile/sanitary requirements.

- Improvement of Media Challenge Process and vaccine production processes.

Contract Biologics Manufacturers

- Specification and procurement of fermentor and cell culture equipment including re-folding tank and large-scale disc-stack centrifuge.

- Manufacturing process transfer for commercial production of bulk drug product.

- Design and implementation of fermentation feed and control strategy at large-scale including characterization of kLa, tip speeds, mixing times and response times.

- Development of process parameters for recovery steps (liquid-liquid extraction, refolding, liquid – liquid separation, filtration and clarification via TFF/centrifugation).

- Project Management and installation oversight for modification of bioreactor vent system.

Biologics Start-Ups

- Screening, due dliligence and selection of contract sites for lead drug product candidates.

- Production, troubleshooting and floor support for MAb production with CHO, Hybridoma and E. coli cultures.

- Detailed reviews for sterile processing equipment, CIP and SIP

- Review and approval of Fermentation and Purification PFDs and Pilot plant production metrics.

- Scale-up from bench to 200L bioreactors and harvest via TFF.

- Technology transfer suitability to pilot plant and manufacturing facility.

Cell Therapy Projects

- Complete oversight for design development, fabrication and testing of large voume perfusion systems, bag filling equipment and bulk drug formuation.

- Review of cell cryo-freezing processes using mechanical and LN2 freezers

Barrier Isolation Vial Filling Line

- Computer system qualification support for a Locally Controlled Environment.

- Development of test protocols for SCADA and PLC.

- SOP development and field testing and troubleshooting.

- Start-up and commissioing support.

Biological Sample Storage and Testing Facility

- Development and execution of testing (IOPQ) for controlled temperature units, terminal HEPA Filters and Biosafety cabinets.

Animal Growth Hormone Facility

- FAT, SAT, commissioning and testing of DCS for fermentation, isolation, purification, lyophilization, formulation, syringe filling and packaging.

- Development of DDS, SOPs and Change Control Procedure.

- AspenTech support for data historian and electronic batch report system.

- Development and execution of validation protocols for automation and process equipment.

Bulk Antibiotic Facilities Renovation

- Development of equipment layouts, PFDs, equipment list and equipment datasheets.

BPS Inc.

119 Jaffrey Road

Malvern, PA, 19355

| Phone: | 484-614-0869 |

| Fax: | 610-296-1454 |