Process and Project Review

Conceptual and Preliminary Design Reviews

Every project; be it an expansion, a modification or a new facility needs to deliver the maximum return from investments. We know it is important that right from the start the design concepts must support fast and efficient project progress. Therefore we consider the many factors such as products, processes, cost, schedule and staffing for effective solutions. As an example, it is often possible to save time by using alternatives to new equipment, smaller equipment or different more efficient use of existing equipment. The key services offered are:

- Basis of Design.

- Scope Development.

- Process Description.

- Process Flow Diagrams.

- Automation/mechanical/process overlap.

Detailed Design Reviews

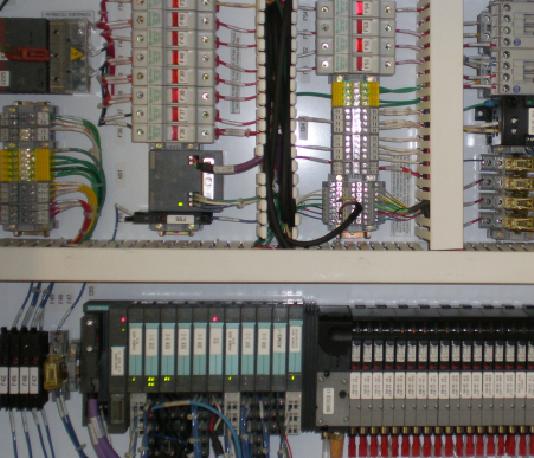

We look to identify and provide the best industry standard solutions for your process automation and control needs. We provide you with an unbiased view of how much automation and controls to employ in specific unit operations and individual skids. As an example, one general approach is to automate only those functions that could be considered truly routine (e.g. CIP/SIP cycles) and provide less automation for the process operations. We understand that automation is a costly solution and evaluate the options by several components such as installed cost, qualification, operator training and equipment and code maintenance. We can offer the following services that are tailored to the biopharm and biologics businesses. Some of these services are often supplied in collaboration with an alliance partner.

We look to identify and provide the best industry standard solutions for your process automation and control needs. We provide you with an unbiased view of how much automation and controls to employ in specific unit operations and individual skids. As an example, one general approach is to automate only those functions that could be considered truly routine (e.g. CIP/SIP cycles) and provide less automation for the process operations. We understand that automation is a costly solution and evaluate the options by several components such as installed cost, qualification, operator training and equipment and code maintenance. We can offer the following services that are tailored to the biopharm and biologics businesses. Some of these services are often supplied in collaboration with an alliance partner.

- GMP facility design.

- Process and scale-up.

- Process utilities.

- Custom and novel process systems.

- Custom and stick-built equipment.

- GAMP documentation and process automation.

- Enhanced design review and peer review.

- User requirements specifications.

- Functional requirements specifications and equipment specifications.

- Equipment data sheets.

- Bid packages and analysis.

- Vendor audits and project management